4D.WATCHER

About the product

Process monitoring of the latest generation

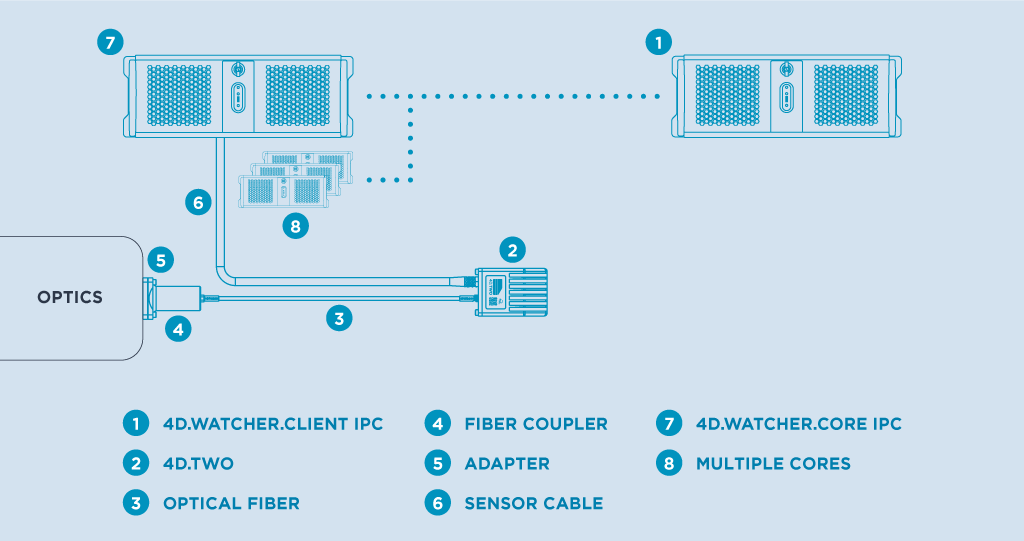

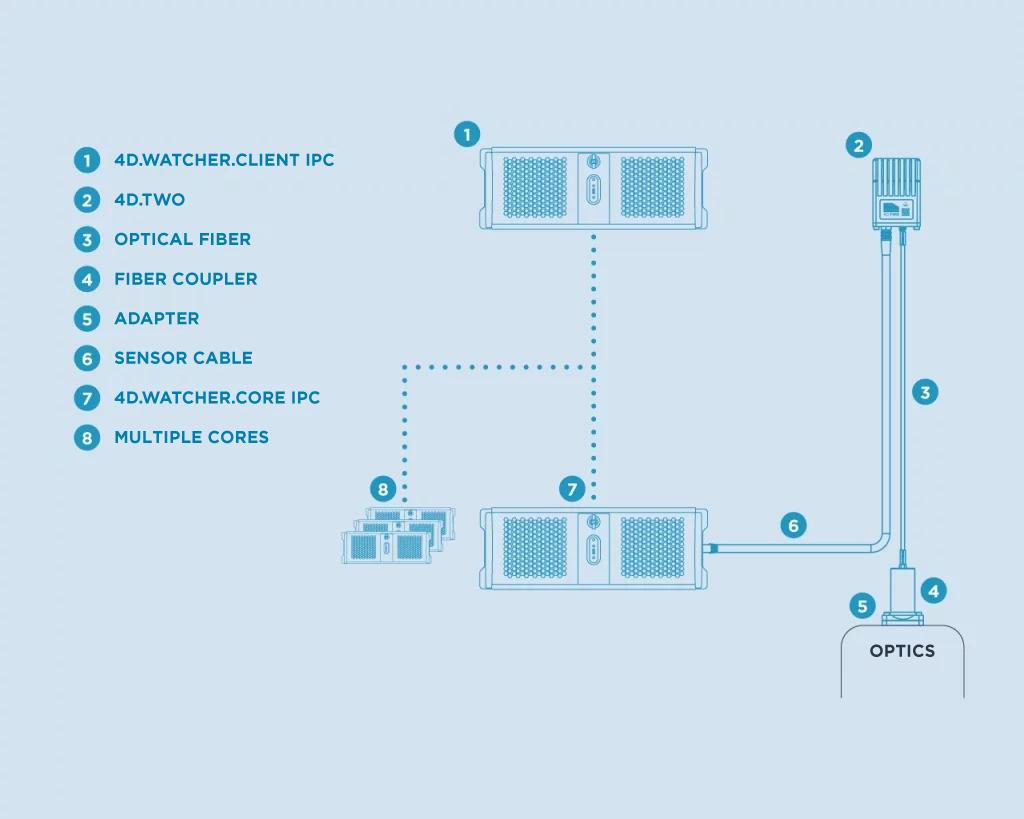

4D.watcher.core receives all data sent from > 4D.TWO (>1M samples/s). It synchronizes them with your PLC data and thus assigns part, group and seam numbers, combines multiple channels according to your specifications and manages complete evaluation.

On the other hand, 4D.watcher.client is the front end for you. It enables you to visualize and parameterize multiple 4D.watcher.cores. It is also your data hub, as it requests all evaluated data of the connected cores.

Features

User friendly. Precise. Intelligent – thanks to high match rate and error classification.

- Error detection: Find process errors more reliably with a number of new technologies such as Lossless Technology, or by selecting the evaluation channels which best match your process deviations. > What is Lossless Technology?

- Combi channels: Combine different channels up to 4 combi channels to classify errors.

- Teach-in process: Start the teach-in process with only one click and the next signals are used to create a scatter band for error classification.

- Traceability: Data storage in a local database for fast access to historical data; long-term storage on your own server solution – we provide a turnkey interface for your IT

What next?

Roadmap

+ Others

Process-to-process breaks

<10 ms possible

(i.e. pipe welding)

Driven by your application experience

⇢ Reduce pseudo faults

⇢ Fault classification

for 3rd party input

for maximum classification

with scatter band

for maximum detection rates

on 10 µs basis

for traceability

with PTP stamps from 3rd party suppliers

loop control

direct output (adjustable ratio/two-color

pyrometer)

Analog signal 0 – 5 V

(closed loop controller)

Is a feature missing, or are you unsure whether we cover it?

+ Others

Process-to-process breaks

<10 ms possible

(i.e. pipe welding)

Driven by your application experience

⇢ Reduce pseudo faults

⇢ Fault classification

for 3rd party input

for maximum classification

with scatter band

for maximum detection rates

on 10 µs basis

for traceability

with PTP stamps

from 3rd party suppliers

with PTP stamps

loop control

direct output (adjustable ratio/two-color

pyrometer)

Analog signal 0 – 5 V

(closed loop controller)

with built-in microphone

via 4D.extender card

Is a feature missing, or are you unsure whether we cover it?

Applications

Process monitoring for the industry …

The 4D.watcher is a versatile tool, which is suitable for different applications, such as:

Automotive industry

Bodywork construction

Battery packs

Fuel cells

Aerospace

Engines

Turbines

Structural components

Medical technology

Implants

Instruments

Catheters

Electronics

Circuit boards

Microchips

Sensors

Metal processing

Pipes

Sheet metal

Profiles

Applications

Process monitoring for the industry …

The 4D.watcher is a versatile tool, which is suitable for different applications, such as:

Automotive industry

Bodywork construction

Battery packs

Fuel cells

Aerospace

Engines

Turbines

Structural components

Medical technology

Implants

Instruments

Catheters

Electronics

Circuit boards

Microchips

Sensors

Metal processing

Pipes

Sheet metal

Profiles

… equipped with the latest sensor technology – our 4D.TWO

4D.TWO is our universal multisensor data source for (almost) every laser application, for which process monitoring is crucial in terms of quality control. It far exceeds the capabilities of other sensors with regard to speed, sensitivity and versatility. It provides >1M samples/s from 42+ single sensors with different physical properties – on one compact device.

- Reduced configuration time

- Detection of the entire range

- Every process event is detected – regardless of how short

4D.TWO is our universal multisensor data source for (almost) every laser application, for which process monitoring is crucial in terms of quality control. It far exceeds the capabilities of other sensors with regard to speed, sensitivity and versatility. It provides >1M samples/s from 42+ single sensors with different physical properties – on one compact device.

- Reduced configuration time

- Detection of the entire range

- Every process event is detected – regardless of how short

Technical data

Data sheets

Technical data sheet (PDF, EN)

Technical data sheet (PDF, EN)

Technical data sheet (PDF, EN)

Technical data sheet (PDF, EN)

Contact us!

If you would like to learn more about our products and services, or would like to request a customized offer, please do not hesitate to contact us. You can contact us by phone, via email or by using our contact form. We look forward to receiving your enquiry!

Contact us!

If you would like to learn more about our products and services, or would like to request a customized offer, please do not hesitate to contact us. You can contact us by phone, via email or by using our contact form. We look forward to receiving your enquiry!