Welding of fuel cells

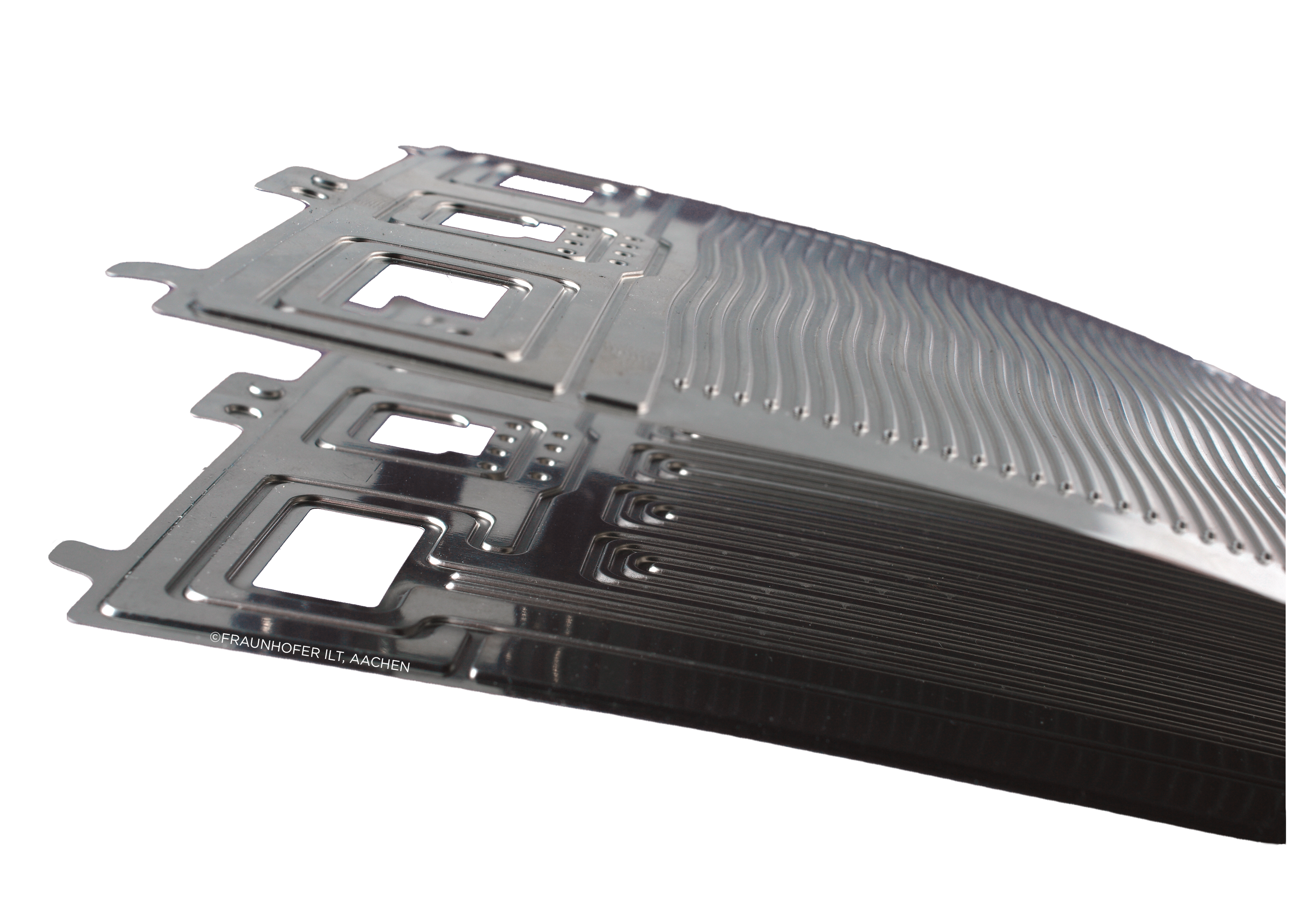

Bipolar plates

The heart of the fuel cell

Bipolar plates

The heart of the fuel cell

Overall, the bipolar plate plays a crucial role in the performance and reliability of fuel cells, which are used in different applications, from vehicles up to stationary energy systems.

The bipolar plate has several important functions in the operation of a fuel cell:

The bipolar plate is responsible for establishing the electrical connection between the individual cells in a fuel cell. It conducts the electrical current from one cell to the next, which generates the total current.

Gas connection

In a fuel cell, hydrogen is used as fuel, and oxygen is used as oxidizing agent. The bipolar plate enables the controlled inflow and outflow of these gases to the electrodes, where the actual electrochemical reactions take place.

Cooling

Fuel cells generate heat during operation. The bipolar plate often serves as heat conduction plate and enables efficient conduction of the generated heat. This is crucial to keep the fuel cell within optimum operating temperatures.

The bipolar plate contributes to the structural integrity of the fuel cell. It supports individual cells and ensures a robust overall construction. Materials such as graphite or stainless steel are often used due to their electric conductivity and corrosion resistance for manufacturing.

The plate can have a special structure, which ensures optimum distribution of gases and coolant in the fuel cell. An even gas flow is ensured through channels or openings, which improves efficiency of the fuel cell.

The bipolar plate is responsible for establishing the electrical connection between the individual cells in a fuel cell. It conducts the electrical current from one cell to the next, which generates the total current.

In a fuel cell, hydrogen is used as fuel, and oxygen is used as oxidizing agent. The bipolar plate enables the controlled inflow and outflow of these gases to the electrodes, where the actual electrochemical reactions take place.

Fuel cells generate heat during operation. The bipolar plate often serves as heat conduction plate and enables efficient conduction of the generated heat. This is crucial to keep the fuel cell within optimum operating temperatures.

The bipolar plate contributes to the structural integrity of the fuel cell. It supports individual cells and ensures a robust overall construction. Materials such as graphite or stainless steel are often used due to their electric conductivity and corrosion resistance for manufacturing.

The plate can have a special structure, which ensures optimum distribution of gases and coolant in the fuel cell. An even gas flow is ensured through channels or openings, which improves efficiency of the fuel cell.

Variants

Graphite and metallic bipolar plates

Both types of bipolar plates play a key role in the optimization of performance and durability of fuel cells. The choice of graphite and metallic plates depends on different factors, including costs, application requirements and environmental conditions. In many cases, they are also used in combination, to use the advantages of both materials.

Graphite bipolar plates mainly consist of expanded graphite, which is produced through heat treatment. These plates provide excellent electric conductivity and are corrosion-resistant. The porous structure enables an improved distribution of the reaction gases, which improves the efficiency of the fuel cell.

In comparison, metallic bipolar plates consist of metal alloys such as stainless steel or titanium. These plates offer high mechanical strength and are thus resistant to pressure and stresses. The smooth surface facilitates sealing and prevents gas leaks.

Graphite bipolar plates mainly consist of expanded graphite, which is produced through heat treatment. These plates provide excellent electric conductivity and are corrosion-resistant. The porous structure enables an improved distribution of the reaction gases, which improves the efficiency of the fuel cell.

In comparison, metallic bipolar plates consist of metal alloys such as stainless steel or titanium. These plates offer high mechanical strength and are thus resistant to pressure and stresses. The smooth surface facilitates sealing and prevents gas leaks.

Precision and efficiency

Fuel cell and laser technology

The welding of fuel cells with laser technology is an advanced method which is used in the manufacturing of fuel cells. This technology provides accurate and efficient joining options for the different components of a fuel cell.

During laser welding, highly intensive laser radiation is focused on the material to be joined. The laser beam melts the material on the weld seam, and a firm connection is formed once cooled. This method enables a very precise introduction of heat and minimizes thermal strains in adjacent areas.

Advantages

Laser welding for fuel cells

Laser welding enables precise small-sized weld seams, which is particularly important, as fuel cells often have complex and fine structures.

The targeted heat introduction reduces the risk of deformations and thermally induced damage to sensitive components, such as bipolar plates.

The high energy intensity of the laser beam enables fast welding processes, which increases production speed.

Laser welding can be performed with different materials, including metals and polymers, which enables adaptation to different fuel cell constructions.

Automation of the laser welding process contributes to the efficiency in the mass production of fuel cells.

Challenges

Balancing of several influences

- Fast process with high volumes: non-detected process deviations and a high rate of pseudo errors

- Material complexity: Fuel cells consist of different layers of materials, which each have specific properties; the laser beam must be optimally adapted to this range in order to generate an efficient weld seam without damaging the sensitive components.

- Fluctuating material: Fluctuations in thickness, alloys and coatings make troubleshooting more difficult

- Thermal influence: Laser welding generates heat, and the fuel cells often contain temperature-sensitive parts; precise control of the thermal effect is crucial to avoid unwanted effects, such as deformations or degradation of the materials

- Size of the fuel cells: a precise focus of the laser beam onto small, complex components requires advanced optical systems and highly developed welding techniques

- Automation: the integration of robotics and advanced control systems is necessary to maximize the efficiency and accuracy of the welding process

Precision. Efficiency. Quality.

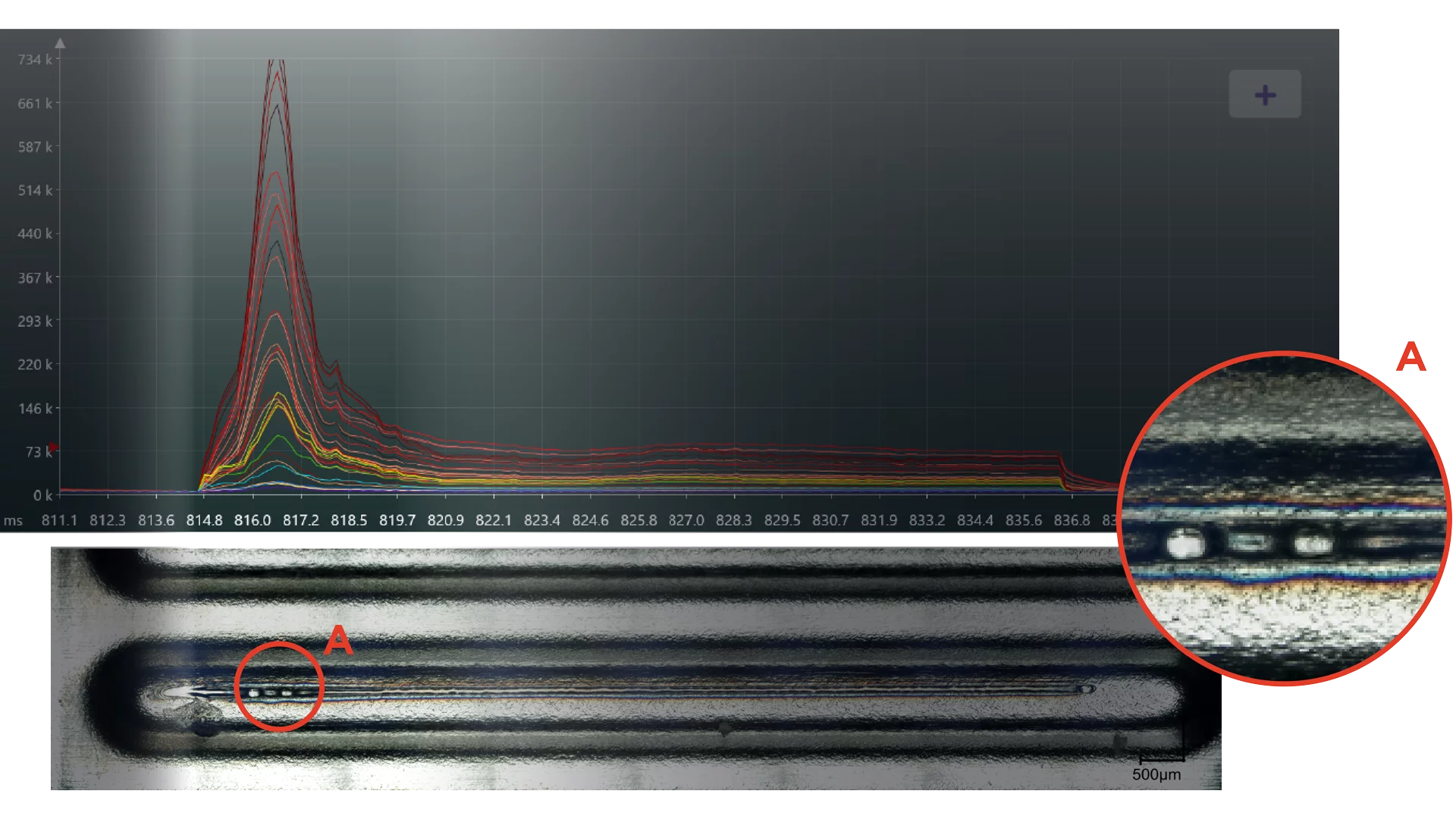

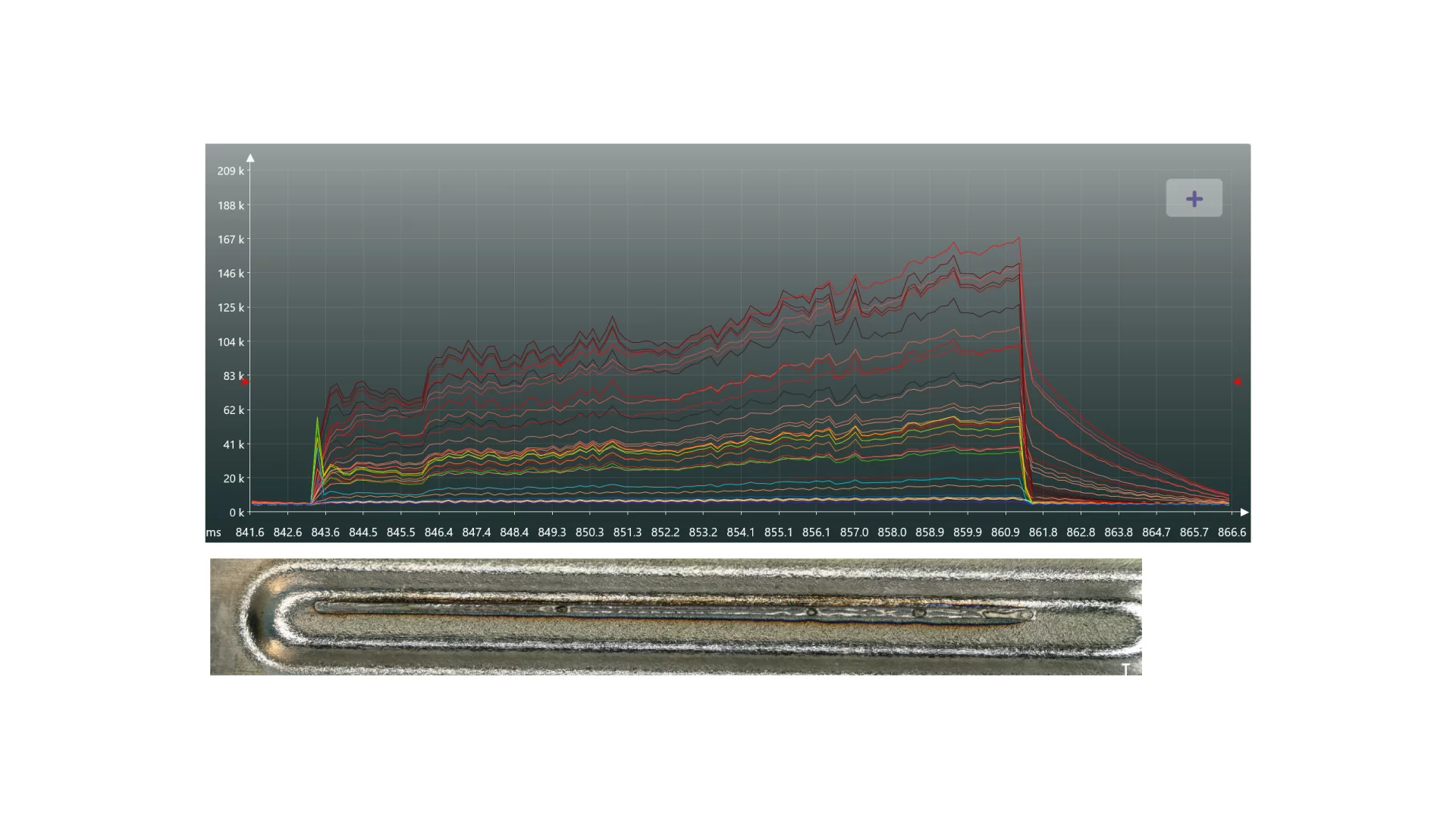

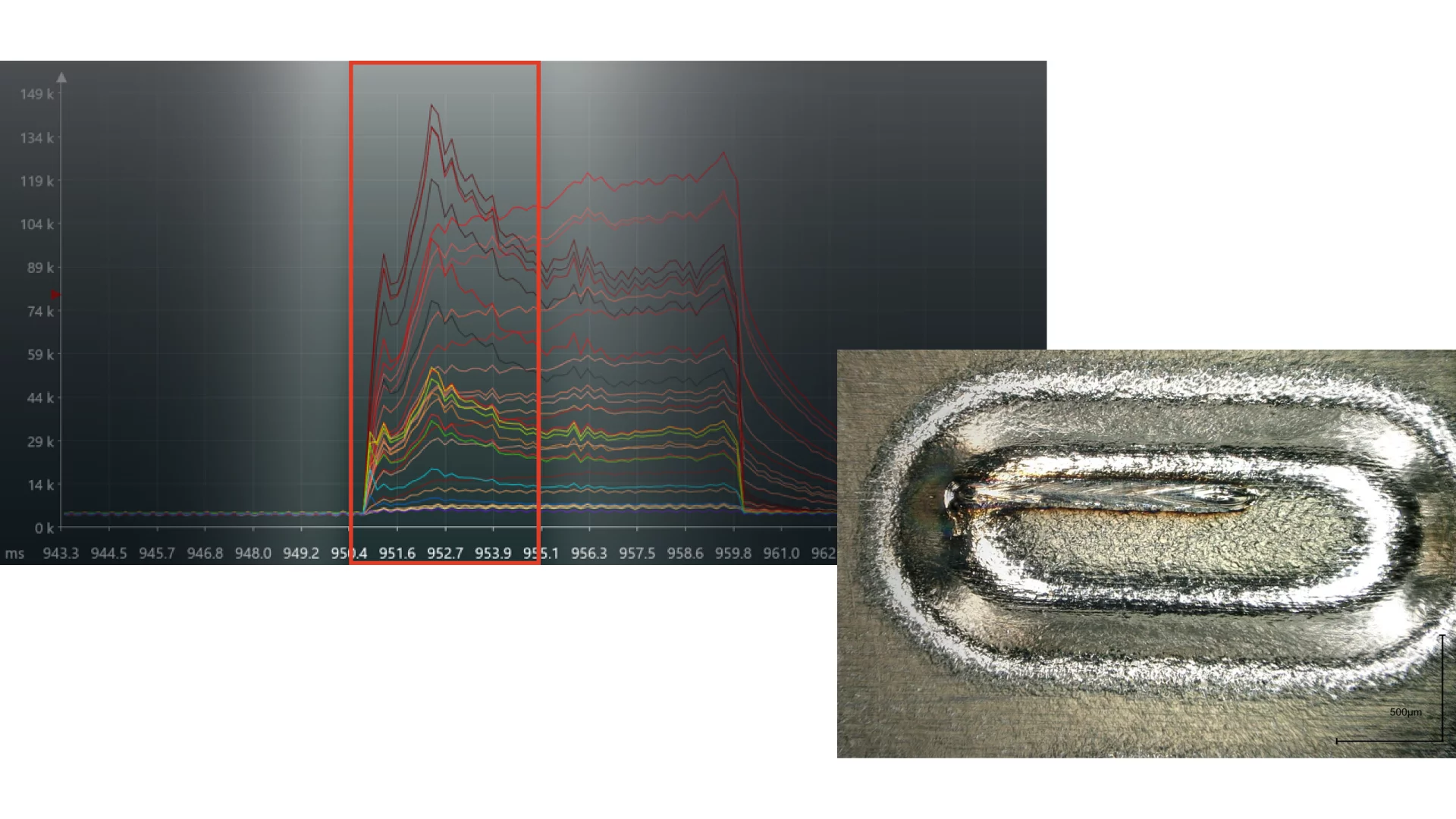

Process monitoring during the welding of bipolar plates

During the laser cutting process, advanced monitoring systems are used to ensure that the exact contours and structures are achieved in accordance with the design specifications. Cameras and sensors continuously monitor the laser beam and positioning of the bipolar plates, to detect any deviations in real time.

Our solution

Thanks to Lossless Technology, the high speeds of > 1 m/s can be monitored reliably and seamlessly.

Contact us!

If you would like to learn more about our products and services, or would like to request a customized offer, please do not hesitate to contact us. You can contact us by phone, via email or by using our contact form. We look forward to receiving your enquiry!

Contact us!

If you would like to learn more about our products and services, or would like to request a customized offer, please do not hesitate to contact us. You can contact us by phone, via email or by using our contact form. We look forward to receiving your enquiry!