Applications

From microelectronics to e‑mobility

Application examples

With our 29-year experience of worldwide installations of process monitoring solutions, we cover almost any laser application.

Our products are suitable for a number of applications – from microelectronics to components for e‑mobility. Regardless of whether the materials used are steel, aluminum, copper or combinations of these materials, our products are designed to meet the customer requirements in fully automatic production lines.

You will find a selection of the laser applications here.

The joining of copper connections is a central manufacturing process of the electric motor. State-of-the-art electric drives are “wound” with rectangular wires instead of round wires. Each of these 100 to 200 hairpin pairs must reliably maintain the electrical conductivity over the service life. If one connection fails, the motor no longer works.

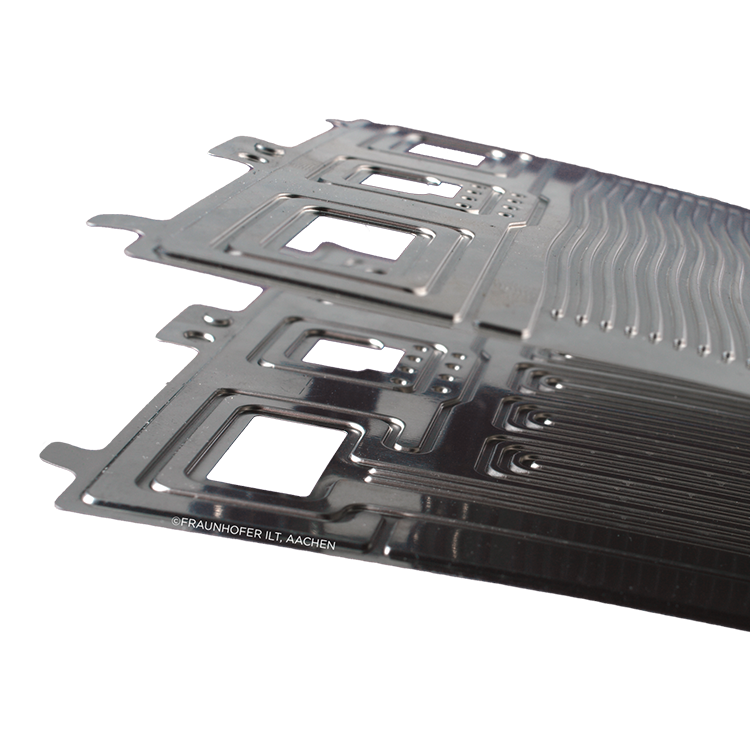

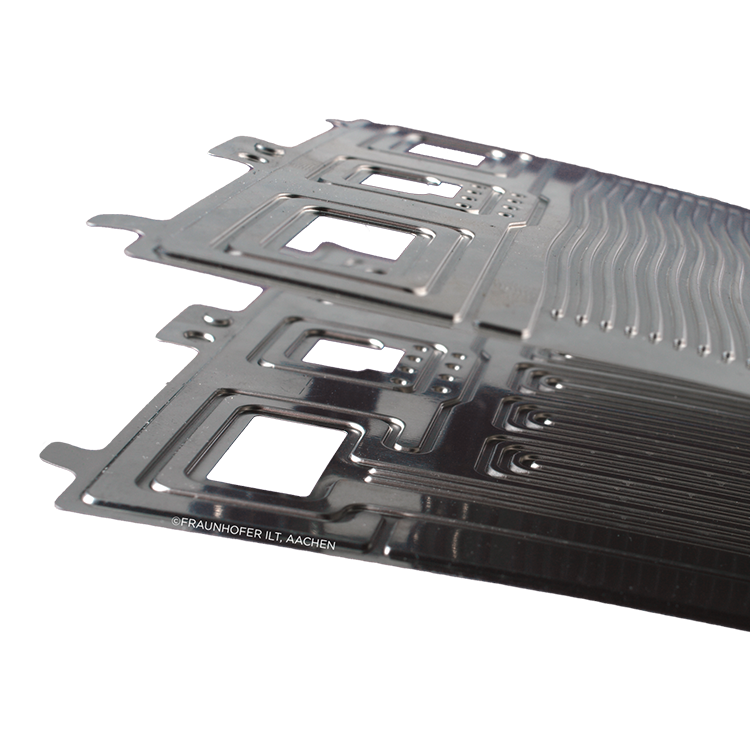

Welding plays a central role to ensure the structural integrity and durability of fuel cells. The precision of these processes is crucial, as fuel cells are used in different applications, from the transport industry to stationary power generation.

Battery welding by laser has got established as an advanced technology, which is used in different industries. This method enables precise and reliable connections in batteries, which optimizes performance and service life. With a focus on efficiency and quality control, battery welding with laser provides an alternative solution for the production of battery components.

The joining of copper connections is a central manufacturing process of the electric motor. State-of-the-art electric drives are “wound” with rectangular wires instead of round wires. Each of these 100 to 200 hairpin pairs must reliably maintain the electrical conductivity over the service life. If one connection fails, the motor no longer works.

Welding plays a central role to ensure the structural integrity and durability of fuel cells. The precision of these processes is crucial, as fuel cells are used in different applications, from the transport industry to stationary power generation.

Battery welding by laser has got established as an advanced technology, which is used in different industries. This method enables precise and reliable connections in batteries, which optimizes performance and service life. With a focus on efficiency and quality control, battery welding with laser provides an alternative solution for the production of battery components.

Your application is not mentioned?

With more than 1,500 installed systems all over the world, we can draw on an wealth of experience. Contact our experts and we will discuss your issue together. We will be pleased to offer you trials on site, so that you can make an initial assessment of whether process monitoring is the best solution for you, and which type.

Contact us!

If you would like to learn more about our products and services, or would like to request a customized offer, please do not hesitate to contact us. You can contact us by phone, via email or by using our contact form. We look forward to receiving your enquiry!

Contact us!

If you would like to learn more about our products and services, or would like to request a customized offer, please do not hesitate to contact us. You can contact us by phone, via email or by using our contact form. We look forward to receiving your enquiry!