Monitoring of laser processes in production

Simple solutions. Defining standards.

Monitoring of laser processes

in production

Simple solutions. Defining standards.

Our products

Process monitoring. Data visualization. Traceability.

The fully automatic process monitoring supplies reliable production data. In addition to our onboarding solutions for statistics, we deliver solutions for data mining of several machines and preconditioned data for long-term storage and traceability on your IT systems.

Our products

Process monitoring. Data visualization. Traceability.

The fully automatic process monitoring supplies reliable production data. In addition to our onboarding solutions for statistics, we deliver solutions for data mining of several machines and preconditioned data for long-term storage and traceability on your IT systems.

Defining standards together with simple solutions.

This is our vision for process monitoring in

an increasingly complex production environment.

Our services

Advice. Commissioning. Training. Worldwide support.

We not only provide you with high-quality products, but also with comprehensive services. We support you in the selection of a suitable sensor for your application, the installation and commissioning of the system, the training of your employees and the maintenance and repair of the system. You can reach us worldwide, and we will advise and actively support you.

Process monitoring happiness

Simple. Transparent. Happy.

Your partner for laser process monitoring

More than 25 years experience in laser technology

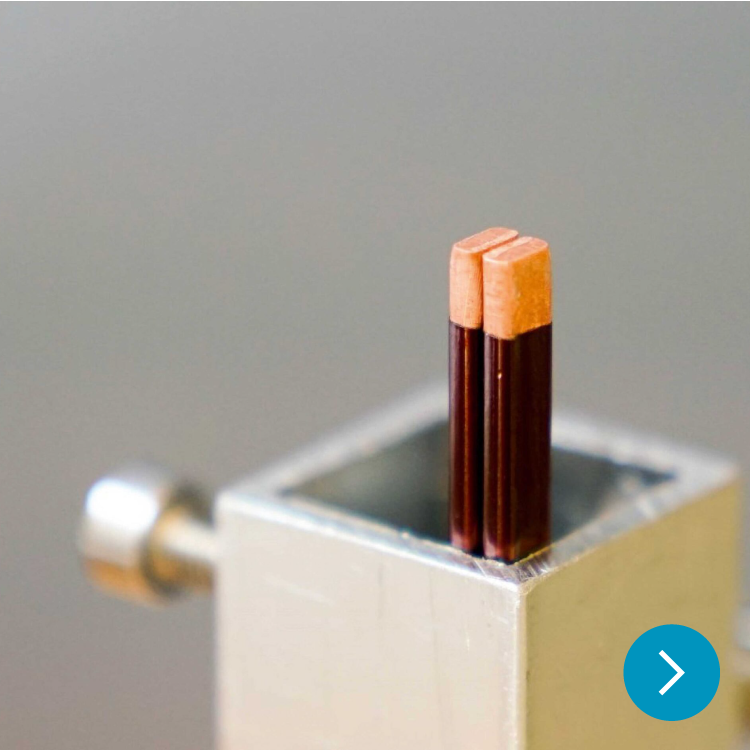

Welcome to 4D Photonics, the independent supplier of application-optimized systems for laser process monitoring. We develop and produce high-quality sensors, which record and evaluate the optical radiation for high-performance laser processes (e.g. welding, powder and wire buildup welding or additive manufacturing, cleaning, surface finish, cutting etc.). Our products enable automated monitoring and quality assurance for different laser processes in the industry.

Process monitoring as

part of quality assurance.

This is our aspiration.

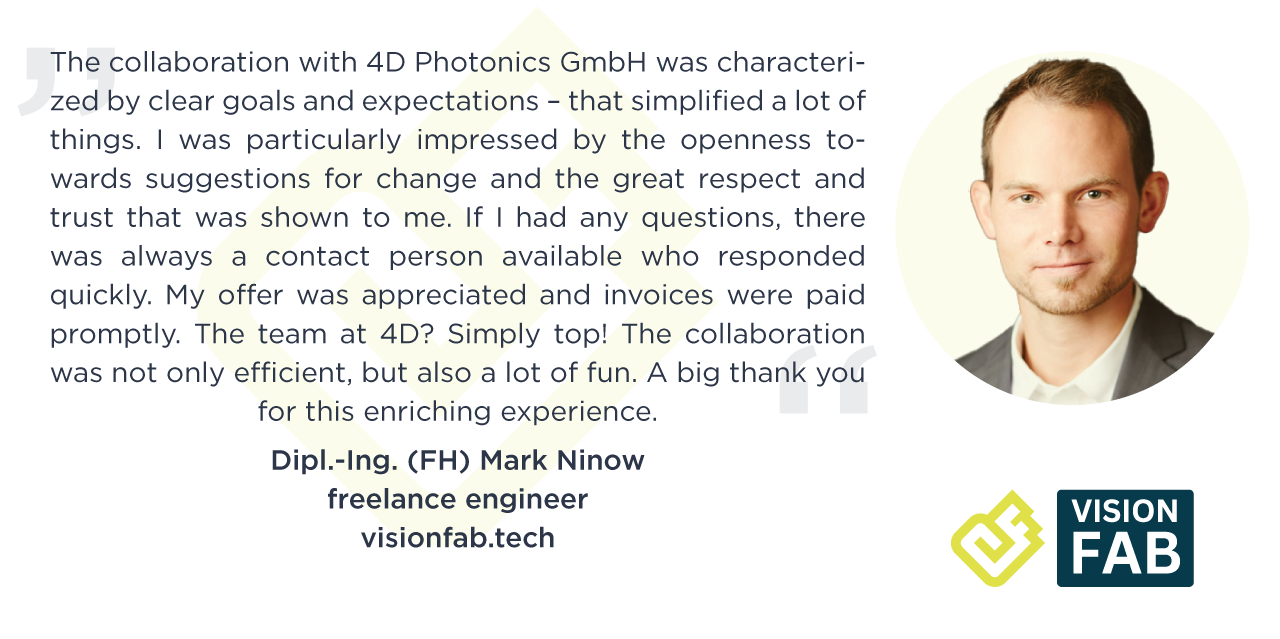

On an equal footing. With respect. Transparent.

Feedback from customers and partners

Then send us a message at info@4d-photonics.com.

Interview

Talk with 4D

Contact us!

If you would like to learn more about our products and services, or would like to request a customized offer, please do not hesitate to contact us. You can contact us by phone, via email or by using our contact form. We look forward to receiving your enquiry!

Contact us!

If you would like to learn more about our products and services, or would like to request a customized offer, please do not hesitate to contact us. You can contact us by phone, via email or by using our contact form. We look forward to receiving your enquiry!