WELDWATCHER®

About the product

The complete solution in process monitoring

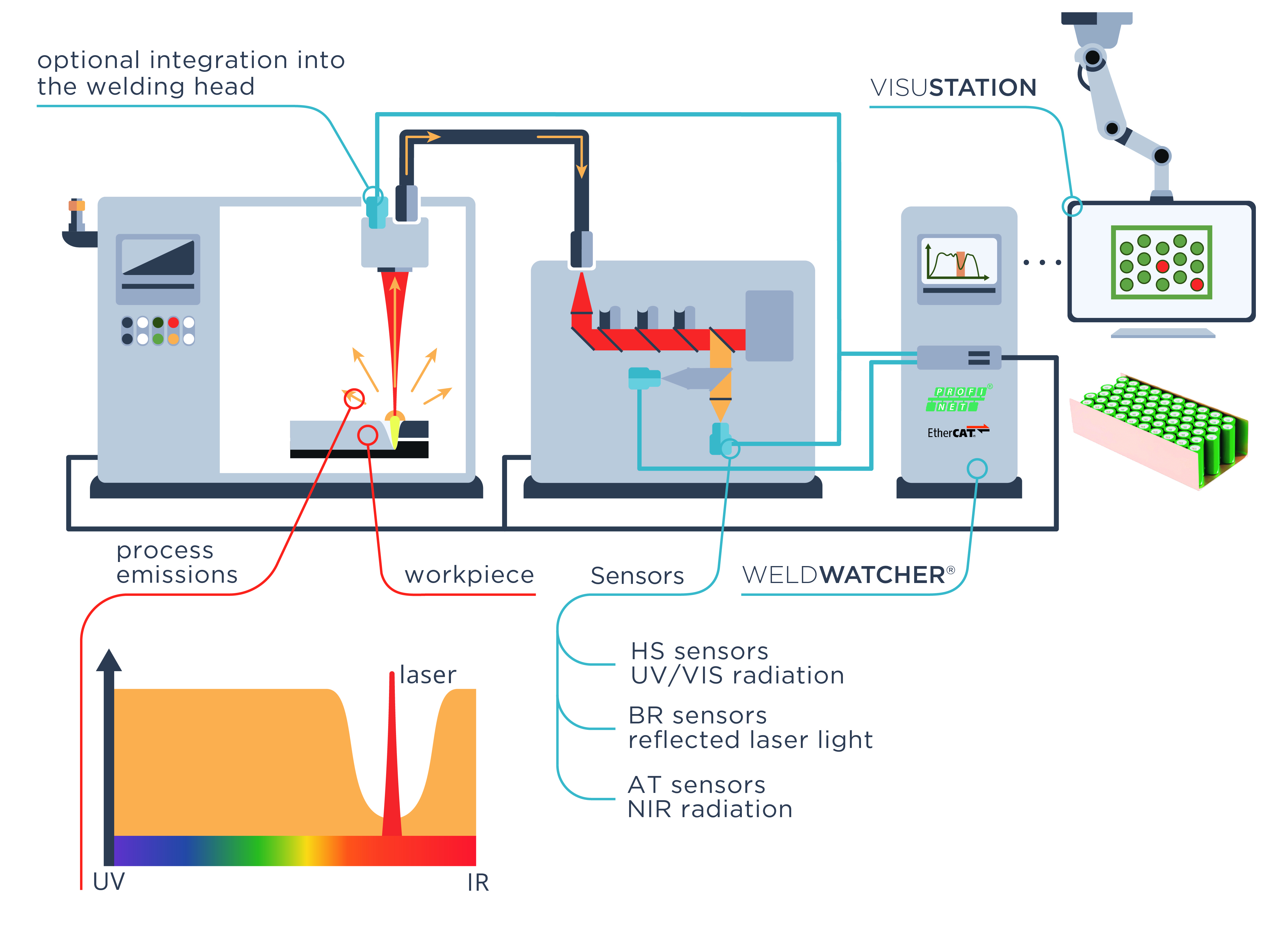

Our main product is the WELDWATCHER®, a sensor which can be integrated into the processing head or the laser. The WELDWATCHER® detects the optical radiation, which is generated during laser welding and laser cutting and analyzes it in real time. This enables the sensor to detect anomalies in the process which correlate with errors in the product, such as pores, splatter or imperfections. The WELDWATCHER® is compatible with different laser types, such as CO2-, Nd:YAG, fiber or diode laser.

Sensor technology

Sensors for the full spectrum

Our sensor families cover the full spectrum from UV/VIS (a.k.a. “plasma”), back reflection to NIR (a.k.a. “temperature”), each available with different sensitivities. All sensors can quickly be adjusted by software during production. We combine or mix multiple sensors in cases where a single sensor does not provide sufficient data for a profound OK/NOK evaluation. In most cases we can maintain the full functionality of your camera or OCT devices.

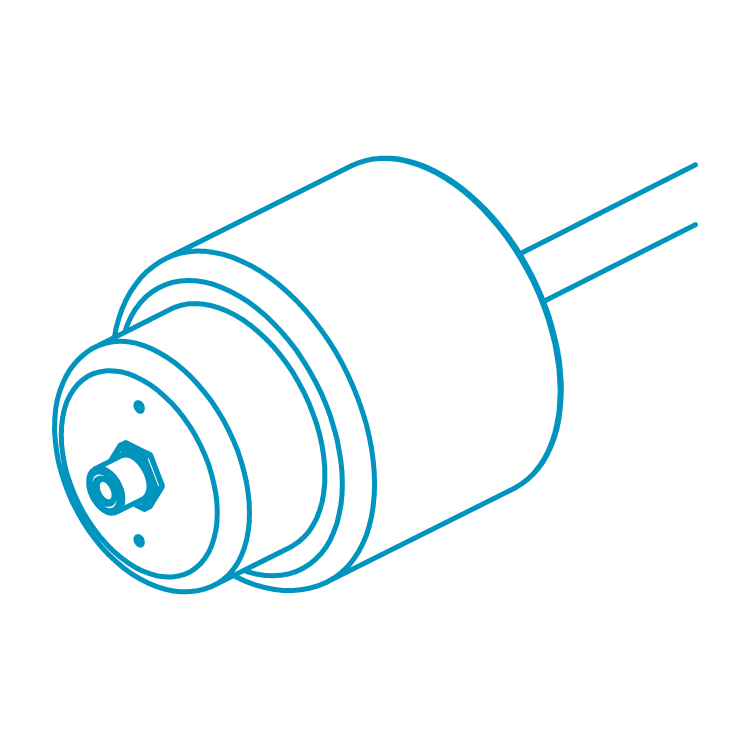

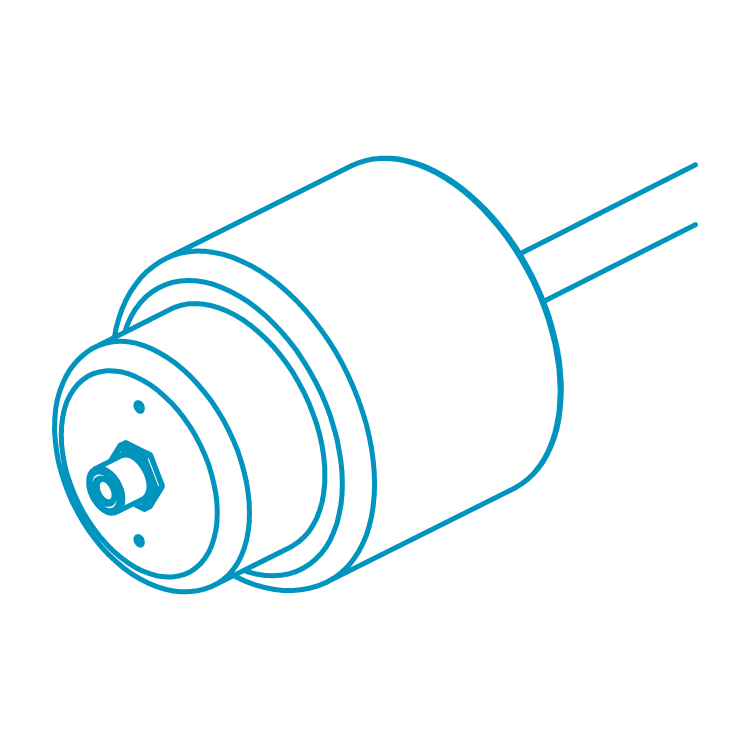

Universal Sensor

For most applications our Universal Sensor housings provide an economic solution especially for unmoved optics or for the integration into the laser source or beam switch. This method eliminates bulky integrations at the processing heads and the use of expensive torsion proof robot cabling.

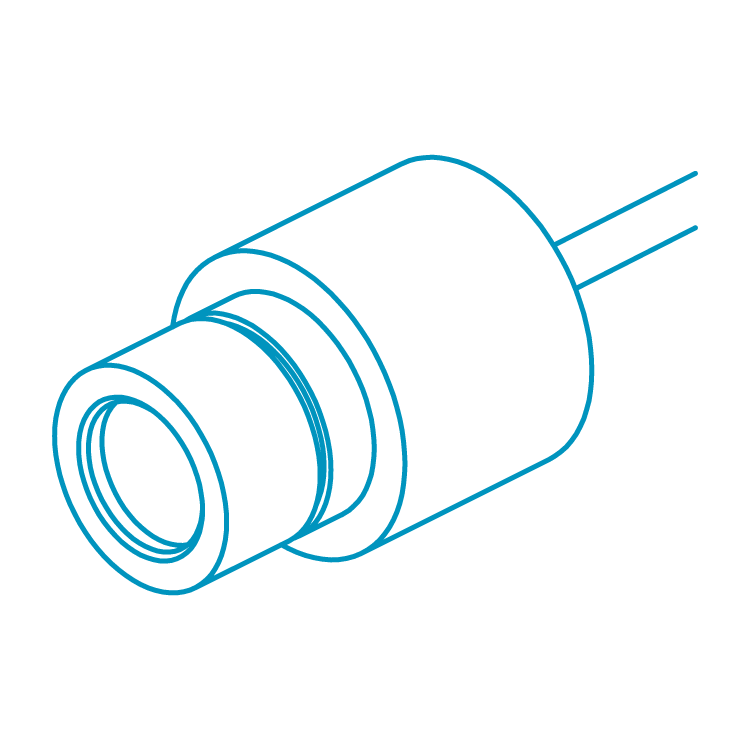

Fiber Sensor

The Fiber Sensors are applicable to common types of fiber lasers. They offer the unique advantages of sensors in lasers without the need of a beam switch: free movement of your optical heads and clean environment in the laser.

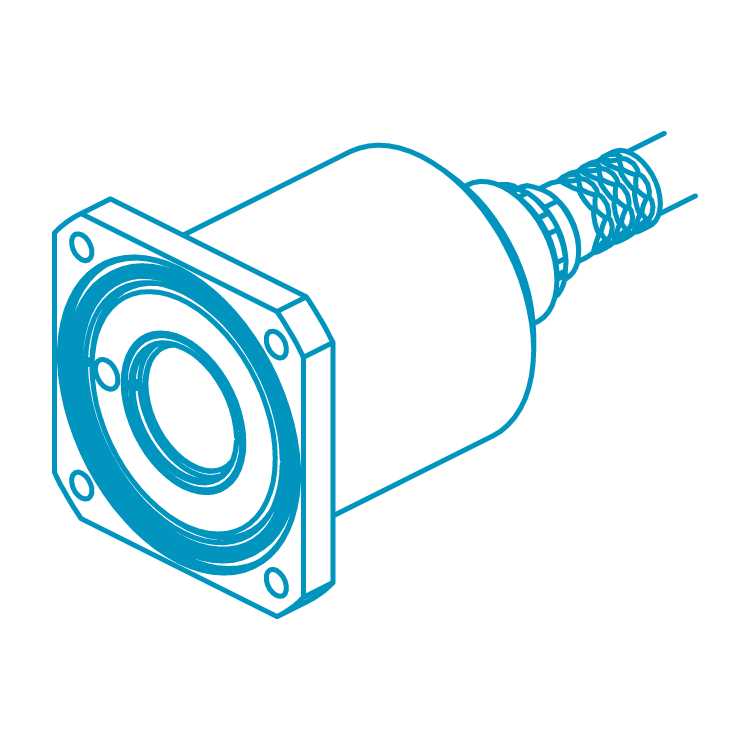

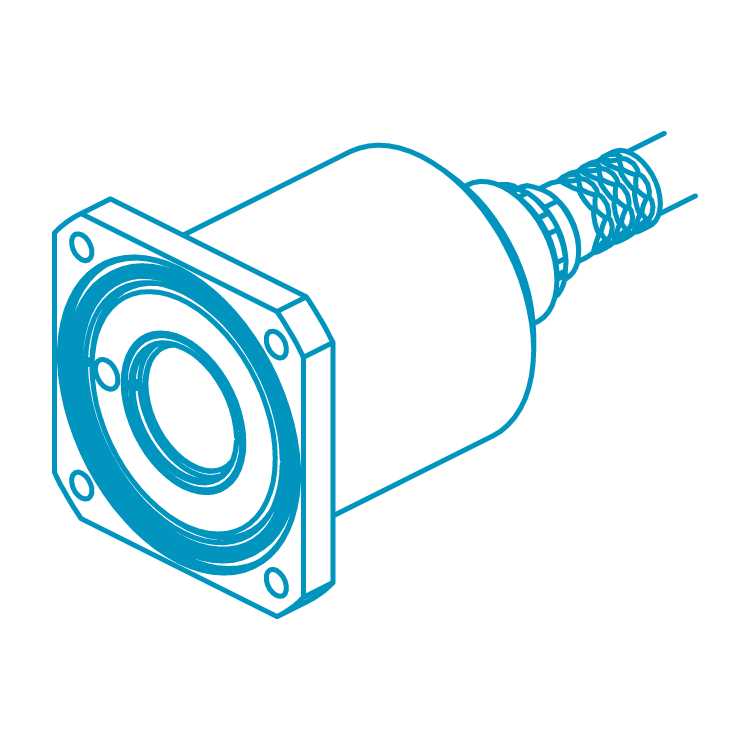

Compact Sensor

Our Compact Sensors are designed for the direct integration into welding heads. They provide IP67 sealed housings and connectors. Rigid robot cables and adapters for most welding heads and scanners make these sensors the #1 choice wherever an integration into the laser is not possible.

Universal Sensor

For most applications our Universal Sensor housings provide an economic solution especially for unmoved optics or for the integration into the laser source or beam switch. This method eliminates bulky integrations at the processing heads and the use of expensive torsion proof robot cabling.

Fiber Sensor

The Fiber Sensors are applicable to common types of fiber lasers. They offer the unique advantages of sensors in lasers without the need of a beam switch: free movement of your optical heads and clean environment in the laser.

Compact Sensor

Our Compact Sensors are designed for the direct integration into welding heads. They provide IP67 sealed housings and connectors. Rigid robot cables and adapters for most welding heads and scanners make these sensors the #1 choice wherever an integration into the laser is not possible.

Installation

Sensor installation options

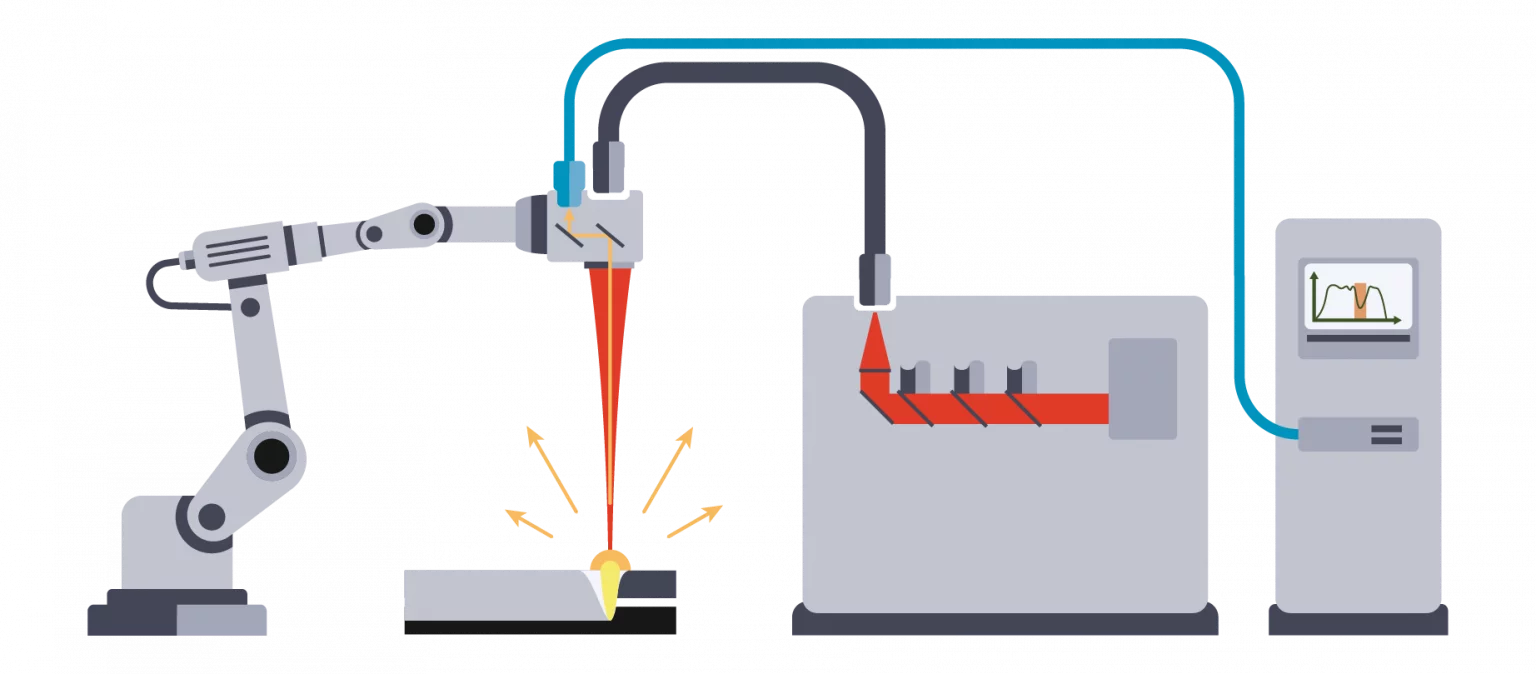

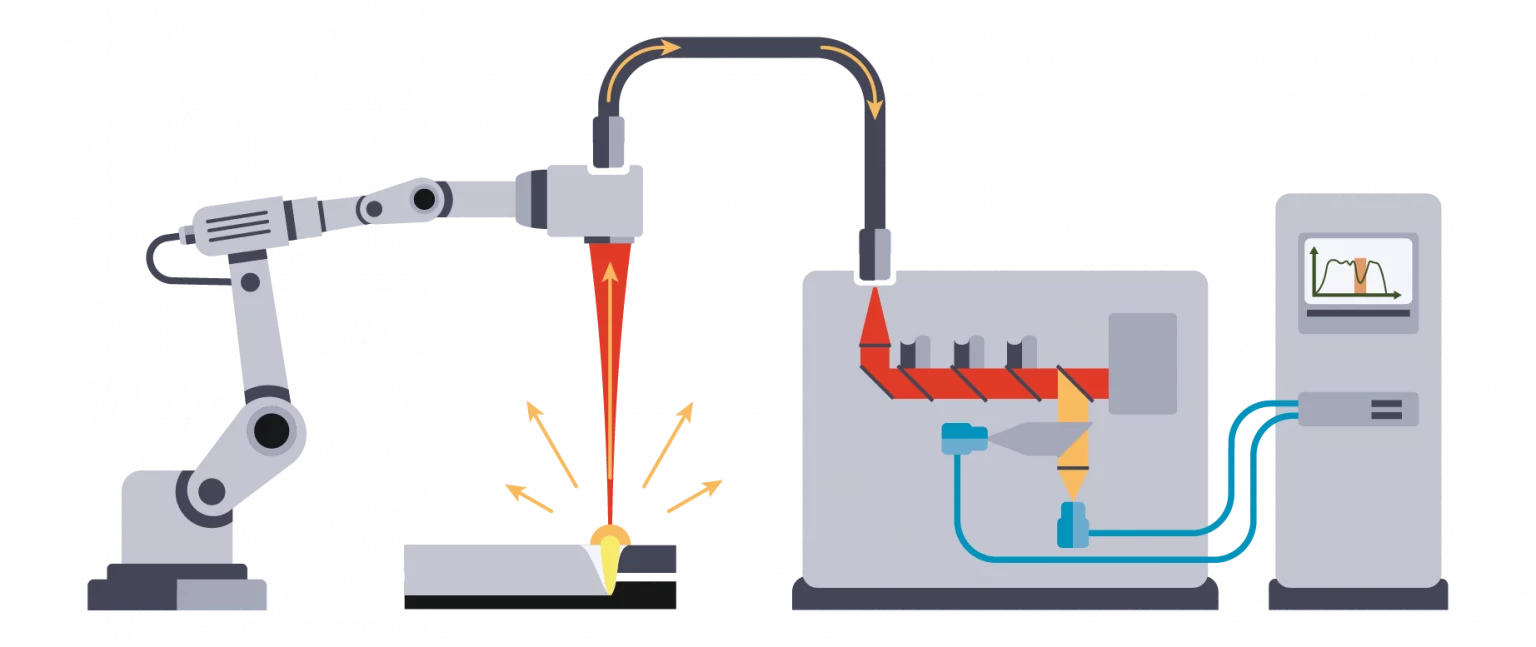

Thanks to numerous adapter modules, we can integrate the sensor either into the processing head (option A) or into the laser or the beam switch (option B). Simply discuss your specific application case with us, and we will find the best solution together with you. In general, both options are available as illustrated below.

In many cases, sensors can be integrated into the laser, providing numerous advantages. Due to this, all beam paths of the laser can be monitored by only 1 WELDWATCHER® . Your processing head maintains its full freedom of movement with this, as the sensor and cable are safely stored in the laser.

The sensors can be directly integrated into the processing head of all established manufacturers. The proximity to the process enables excellent signal quality here.

In many cases, sensors can be integrated into the laser, providing numerous advantages. Due to this, all beam paths of the laser can be monitored by only 1 WELDWATCHER® . Your processing head maintains its full freedom of movement with this, as the sensor and cable are safely stored in the laser.

Integration

Seamless integration into your production environment

Successful use of process monitoring is ensured via communication to the system control. Here, the evaluations of the processes are assigned to the component numbers. This allows the errors in the processes of the respective component to be traced again later on. Different sensors are available. We will select the best combination of sensors for you, tailored to your application.

Technical data

Data sheets

Contact us!

If you would like to learn more about our products and services, or would like to request a customized offer, please do not hesitate to contact us. You can contact us by phone, via email or by using our contact form. We look forward to receiving your enquiry!

Contact us!

If you would like to learn more about our products and services, or would like to request a customized offer, please do not hesitate to contact us. You can contact us by phone, via email or by using our contact form. We look forward to receiving your enquiry!