Hairpin stator

Advanced manufacturing of electric motors

Hairpin stator

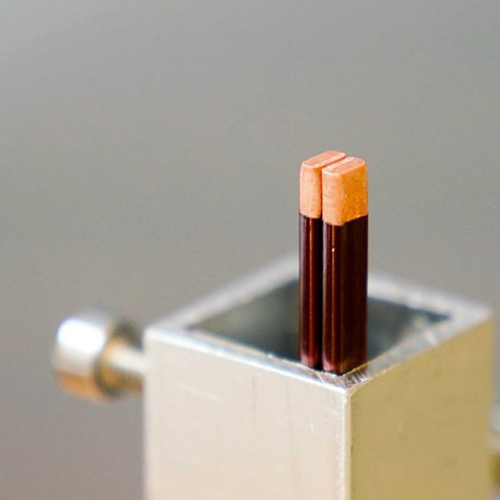

The welding of hairpins by laser is an advanced technology, which is widely used in the manufacturing of electric motors and generators. Hairpins are special copper or aluminum profiles, which are formed into a bobbin shape and represent a key component for the performance of electrical drive systems. The use of laser welding in this context enables precise and controlled connections between the hairpin ends, which ensures an efficient transmission of electricity and thermal stability.

Central motor component

Design of the stator of a hairpin motor

The stator of a hairpin motor represents a central component, which significantly contributes to the performance and efficiency of the motor. Compared to conventional electric motors, the hairpin motor is characterized by an innovative design of its stator.

The stator usually consists of a laminated iron core, which serves to strengthen the magnetic field and maximize the efficiency of the energy conversion. The hairpin technology refers to the special form of the coils in the stator. Instead of traditional wire windings, hairpins are used here – specially formed, flat profiles made of highly conductive copper or aluminum.

The hairpins are positioned in a precise geometrical arrangement, to ensure optimal utilization of the magnetic flow. This innovative approach not only maximizes the electrical conductivity, but also minimizes losses due to eddy currents, and improves thermal stability of the stator.

The innovative design of the stator in a hairpin motor contributes to achieving higher power densities, improved efficiencies and an overall more compact design. This makes hairpin motors an attractive choice for applications where efficiency, compactness and performance are a crucial factor, such as for example e‑mobility and other high-performance applications.

Diligence and accuracy

Manufacturing of hairpin stators

The manufacturing of hairpin coils occurs via an automated winding process, which ensures a precise arrangement and alignment. After winding, the hairpin windings are inserted in the stator, whereby particular attention is placed on the correct positioning and fixation. This step requires advanced machines and robotics, to achieve high accuracy.

After placement, the hairpin windings are connected to each other, to ensure electrical continuity. This can be achieved through welding or other connection techniques. This is then followed by isolation of the windings, to prevent electrical short circuits and ensure the integrity of the stator.

The complete hairpin stator runs through final quality inspections, in which parameters such as electrical resistance, isolation quality and overall performance are checked. This process ensures that the produced hairpin stators correspond to the high standards of the electric motor industry and ensure reliable performance in different applications.

Complex process landscape

Challenges during laser welding of hairpins

The application of laser welding in the manufacturing process of hairpin stators, particularly for the connection of the conductive hairpin windings, presents a number of challenges. The precision, thermal influence, material selection and automation are crucial aspects requiring careful attention.

- Precision requirements: Hairpin windings require extremely precise positioning and alignment during the laser welding process, small deviations can result in quality issues and losses in performance

- Thermal influence: the laser welding process generates heat which can influence adjacent materials; control of the thermal effect to avoid damage to sensitive parts

- Material selection: Selection of materials which can be welded and are suitable for the requirements of the hairpin stator; consideration of the conductivity and as well as heat resistance of the materials

- Automation and robotics: Integration of highly developed robotic systems, to ensure the precise positioning and fixation of the hairpin windings; automation of the entire laser welding process for efficiency and consistency

- Weld seam quality: Ensuring a consistent weld seam without defects or irregularities; monitoring and control of the welding parameters for optimum seam quality

- Process speed: Optimization of the laser welding quality to meet the production requirements without affecting the quality; consideration of cycle times and throughput rates

- Quality control: Implementation of precise quality control procedures to detect welding errors early; integration of imaging technologies or inspection systems

- Cost management: efficient utilization of resources and energy to minimize the overall costs of the laser welding process; consideration of investment costs with regard to laser welding equipment

Precision. Efficiency. Quality.

Our solution

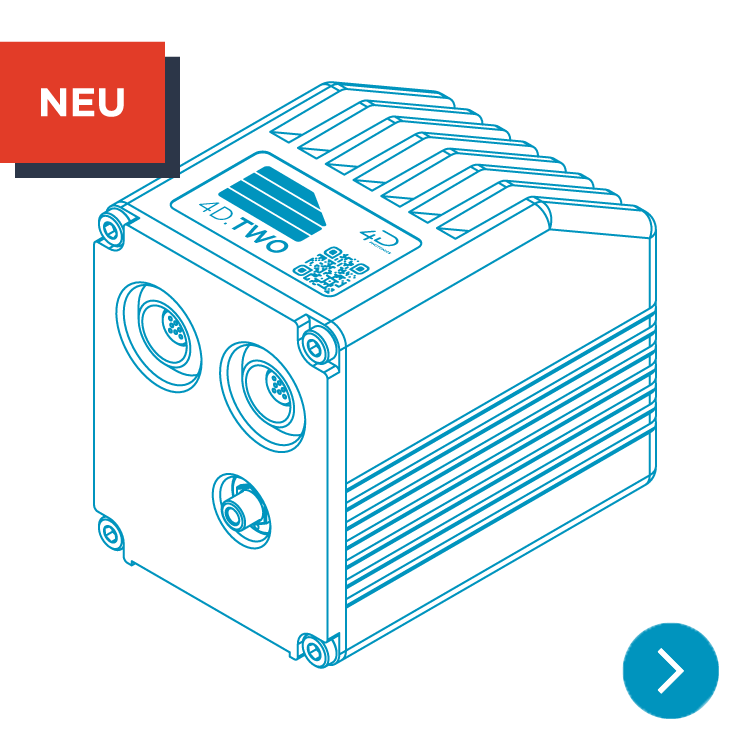

Thanks to the high dynamic range of the 4D.TWO, you can detect process deviations with a comparatively low rate of pseudo errors. With the combination of channels into combi channels, you also save time during troubleshooting, as you can classify errors.

These topics might also be of interest to you

Contact us!

If you would like to learn more about our products and services, or would like to request a customized offer, please do not hesitate to contact us. You can contact us by phone, via email or by using our contact form. We look forward to receiving your enquiry!

Contact us!

If you would like to learn more about our products and services, or would like to request a customized offer, please do not hesitate to contact us. You can contact us by phone, via email or by using our contact form. We look forward to receiving your enquiry!