Battery welding

e‑mobility

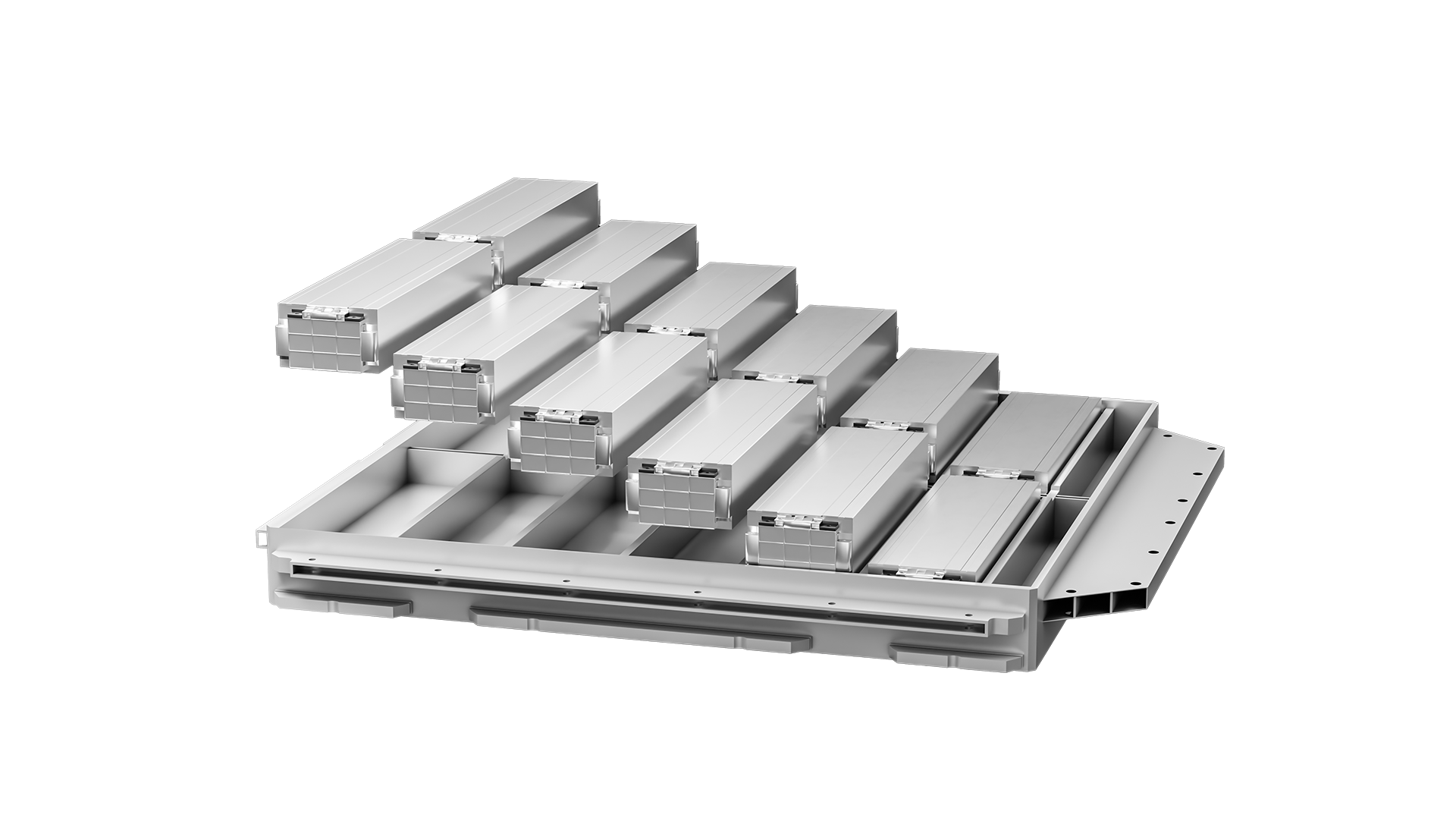

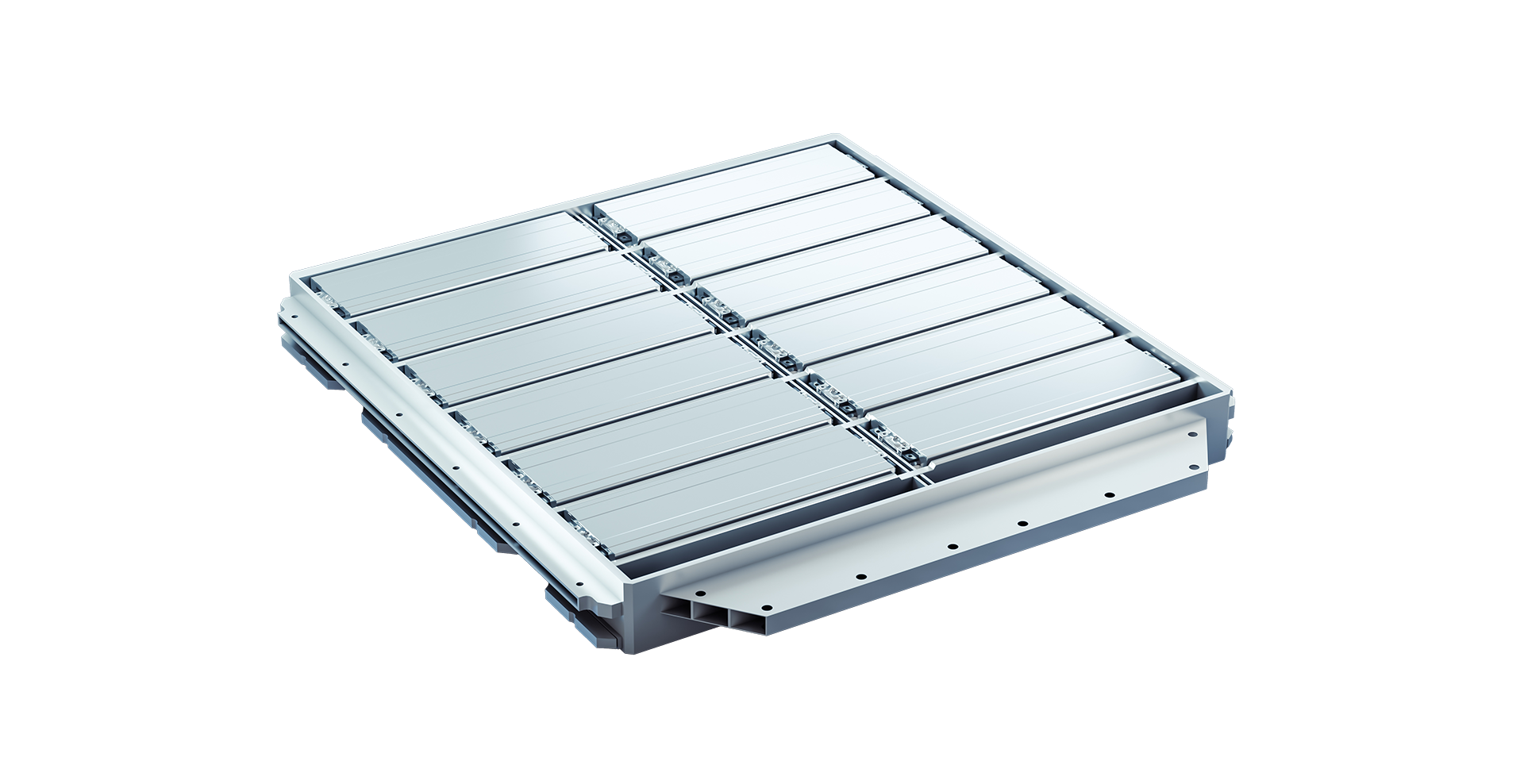

Battery modules

Precision and efficiency

Battery welding with laser

Battery welding with laser has become a highly precise and efficient method in the manufacturing of batteries. This technology offers a number of advantages compared to conventional welding processes.

One crucial aspect is the precision of the laser beam, which can be focused specifically on the areas to be weld shut. This produces the finest weld seams, which are of enormous importance in particular in applications with small battery cells. The precise control of the laser beam also enables the adjustment of the welding parameters in order to join different materials and thicknesses.

The high energy concentration of the laser beam ensures fast and efficient heat transfer during the welding process. This reduces the thermal load of the adjacent areas and minimizes deformations or damage to the battery components. The contactless nature of the laser beam also prevents possible contaminations or wear, which can occur with conventional welding methods.

Automated laser battery welding systems enable high production speed and consistency. The integration of robotics and progressive control systems ensures precise positioning of the battery components for every welding process.

Furthermore, laser battery welding provides the flexibility to support different battery architectures and designs. From small button batteries to large battery packs, different configurations can be combined with optimum precision and efficiency.

Challenges

Speed and fluctuations

- Fast process with many variants: non-detected process deviations and a high rate of pseudo errors

- Fluctuating process: Large number of factors hamper troubleshooting

Precision. Efficiency. Quality.

Process monitoring during the welding of batteries

Process monitoring during battery welding with laser is crucial to ensure highest quality and reliability in the manufacturing of batteries. State-of-the-art technologies enable precise monitoring of every step of the welding process.

Our solution

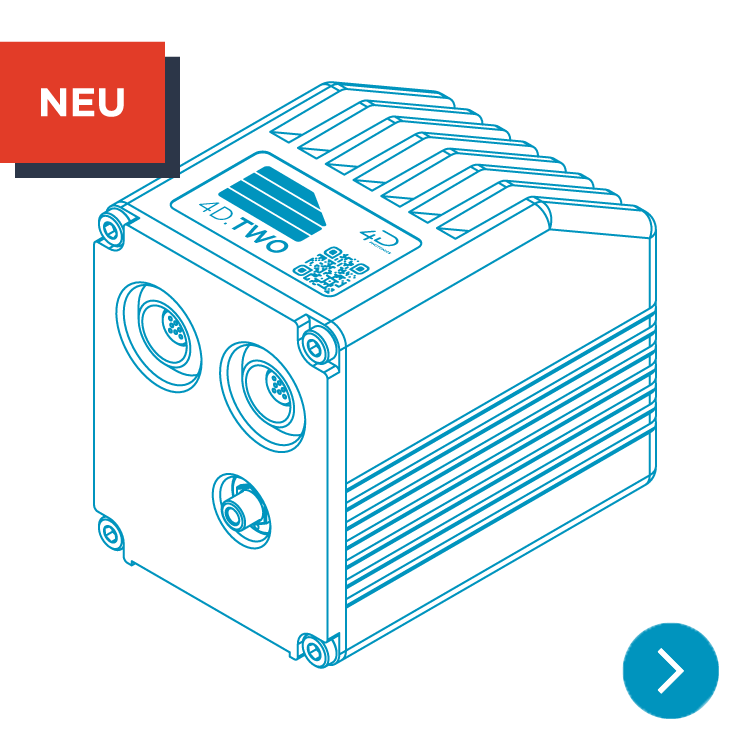

Thanks to the high dynamic range of the 4D.TWO, you can detect process deviations with a comparatively low rate of pseudo errors. With the combination of channels into combi channels, you also save time during troubleshooting, as you can classify errors.

Contact us!

If you would like to learn more about our products and services, or would like to request a customized offer, please do not hesitate to contact us. You can contact us by phone, via email or by using our contact form. We look forward to receiving your enquiry!

Contact us!

If you would like to learn more about our products and services, or would like to request a customized offer, please do not hesitate to contact us. You can contact us by phone, via email or by using our contact form. We look forward to receiving your enquiry!