4D.TWO

The next generation of process monitoring

4D.TWO

The next generation of process monitoring

Not the answer to life, the universe and all

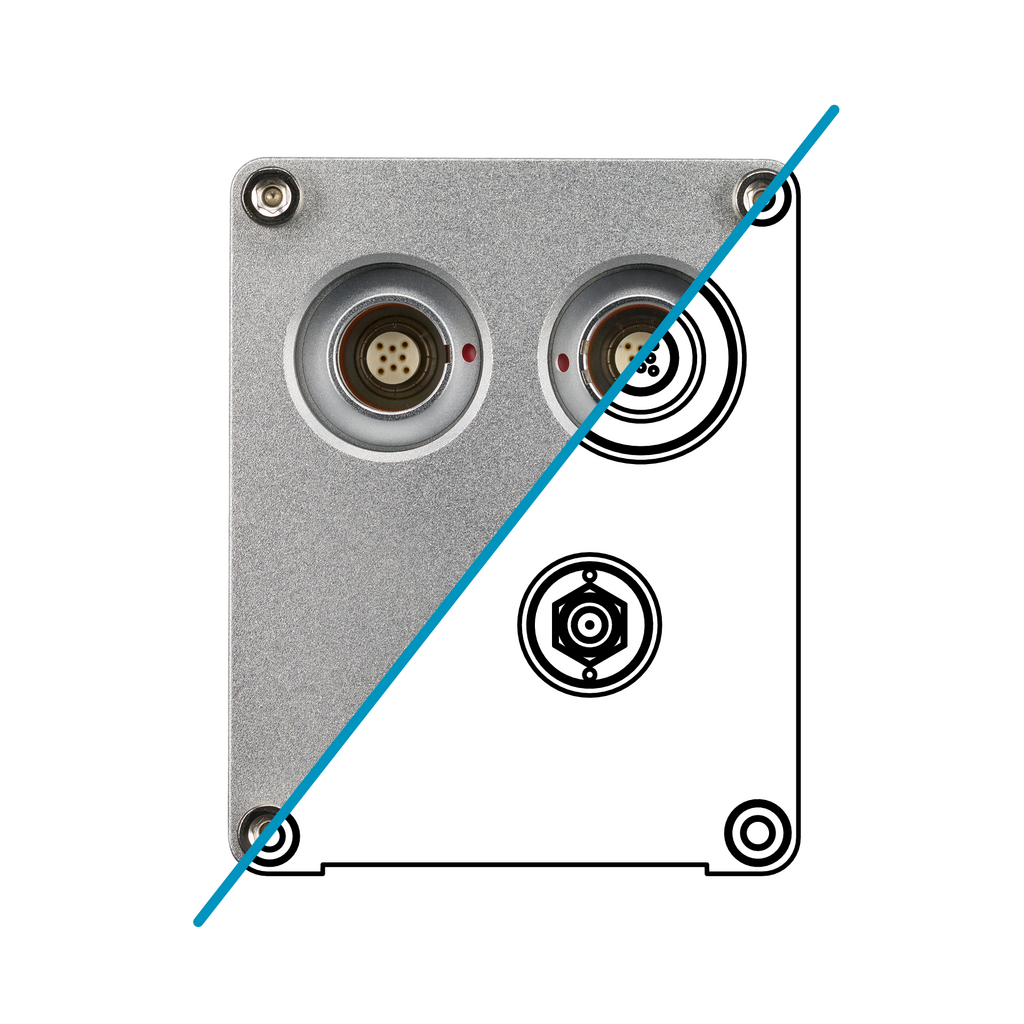

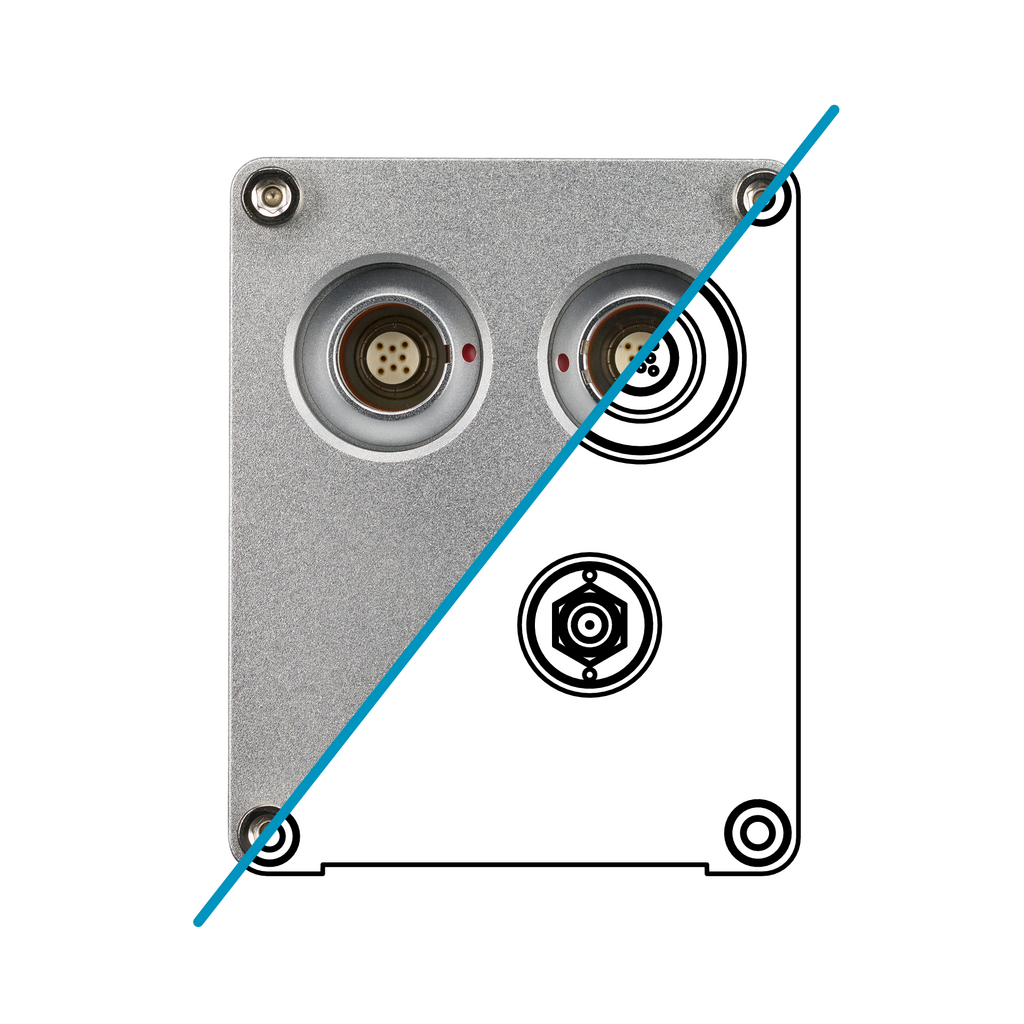

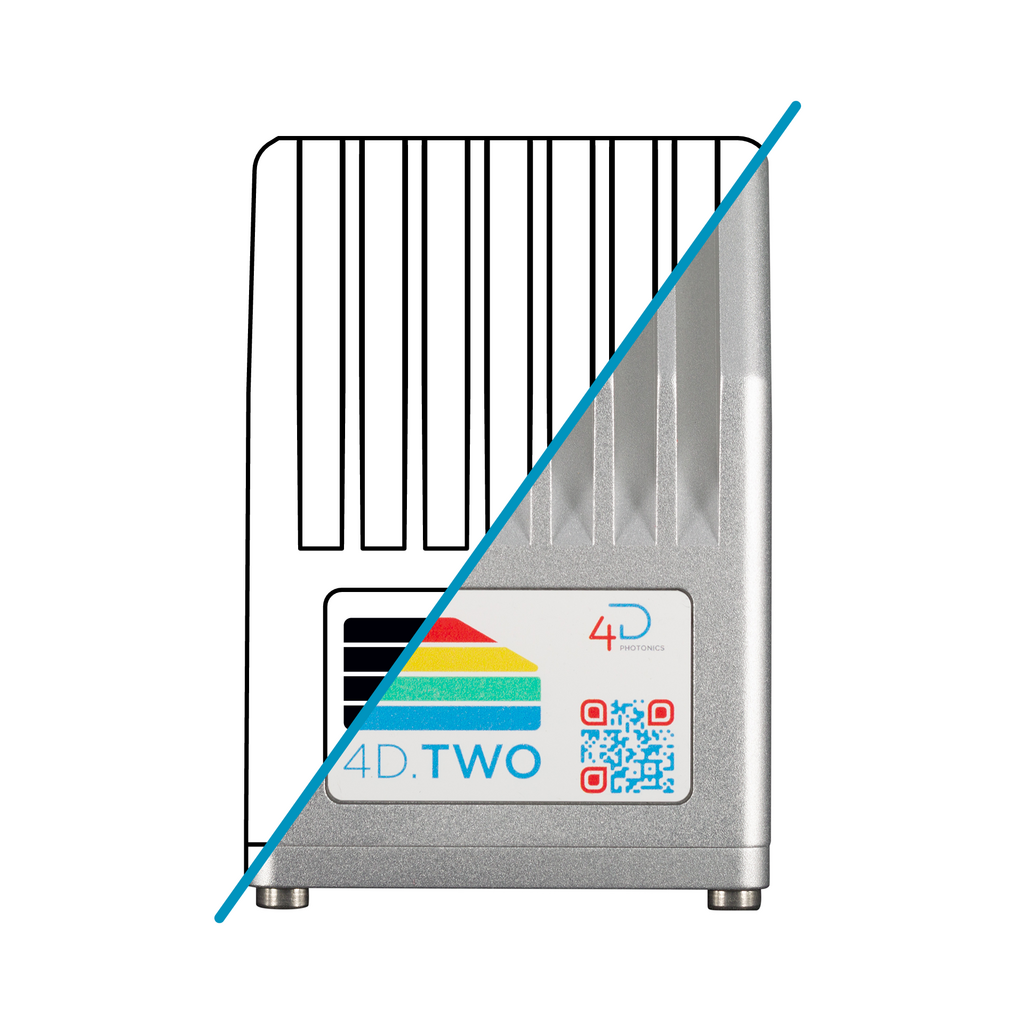

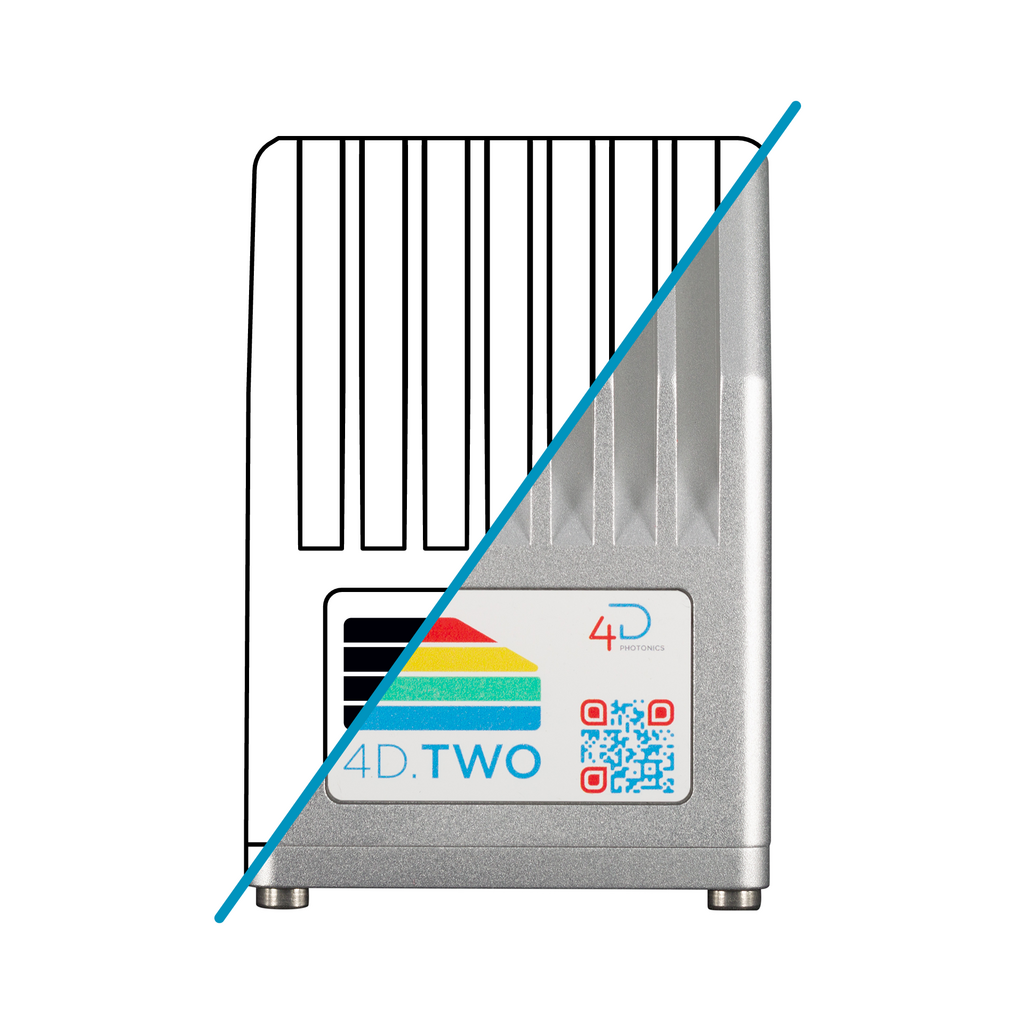

4D.TWO is your universal multisensor data source for (almost) every laser application, for which process monitoring is crucial in terms of quality control. It far exceeds the capabilities of other sensors with regard to speed, sensitivity and versatility. It provides >1M samples/s from 42+ single sensors with different physical properties – on one compact device.

Not the answer to life, the universe and all

4D.TWO is your universal multisensor data source for (almost) every laser application, for which process monitoring is crucial in terms of quality control. It far exceeds the capabilities of other sensors with regard to speed, sensitivity and versatility. It provides >1M samples/s from 42+ single sensors with different physical properties – on one compact device.

Our most important objectives for your applications

Increase the accuracy of process monitoring.

Classify errors.

But instead to most questions regarding the laser process

4D.TWO simultaneously records the complete ranges in the visible (VIS) as well as the near-infrared (NIR) wavelength range – with 16 channels in the VIS and 16 channels in the NIR. In addition to these spectrally resolved channels, the 4D.TWO has channels or order 0 for VIS, NIR and back reflection. With these channels, the spectral ranges are fully detected with sampling rates of up to 100 kHz.

But instead to most questions regarding the laser process

4D.TWO simultaneously records the complete ranges in the visible (VIS) as well as the near-infrared (NIR) wavelength range – with 16 channels in the VIS and 16 channels in the NIR. In addition to these spectrally resolved channels, the 4D.TWO has channels or order 0 for VIS, NIR and back reflection. With these channels, the spectral ranges are fully detected with sampling rates of up to 100 kHz.

Detect shortest events – thanks to Lossless Technology

With Lossless Technology, we detect very short deviations in your laser processes. Events of <40 µs can be reliably detected in the event of a signal change (decrease or increase by 100 %).

Example: At brisk 1000 mm/s feed, this is only 40 µm. So smaller than most laser spots. Effectively less than a hair’s breadth.

We only require moderate measurement rates for this, thus decreasing the required data volume from all 32 optical channels to 25% already for the raw data, compared to 3 channels at 250 kHz each.

Your advantages

Increase your productivity

by reducing your reject rate

Less pseudo errors

due to more precise selection and combination of channels

Increased productivity

due to reduced downtimes

Find the cause of you issue more quickly, by

classifying errors

Your advantages

Increase your productivity

by reducing your reject rate

Less pseudo errors

due to more precise selection and combination of channels

Increased productivity

due to reduced downtimes

Find the cause of you issue more quickly, by

classifying errors

Fast. Precise. Tailored to your requirements.

- ONE sensor for all your applications – tailored to every application with software configuration. Less training for your staff, more company-wide standards.

- Fast support worldwide. Most settings in the software, less support required on site. Use the possibilities of remote maintenance.

- AI, Big Data, machine learning – however you call it, use the advantages of the data volume and create your own USPs.

Fast. Precise. Tailored to your requirements.

- ONE sensor for all your applications – tailored to every application with software configuration. Less training for your staff, more company-wide standards.

- Fast support worldwide. Most settings in the software, less support required on site. Use the possibilities of remote maintenance.

- AI, Big Data, machine learning – however you call it, use the advantages of the data volume and create your own USPs.

Be smart. Adapt. Benefit. Independent of process and application.

- Welding

- 3D printing

- Structuring

- Heat treatment

- Cleaning

- Cutting

- LPBF

- Coating

- Laser bonding

- Hard soldering

- Drilling

- |

- Battery cells

- Bipolar plates

- e‑mobility

- Hydrogen

- Automotive

- Aerospace

- Medical products

- Electrical components

Data sheet

Patent

The respective patent with the title Device for the spectrally resolved detection of optical radiation (file number DE: 10 2021 111 892.1) can be found here.

Contact us!

If you would like to learn more about our products and services, or would like to request a customized offer, please do not hesitate to contact us. You can contact us by phone, via email or by using our contact form. We look forward to receiving your enquiry!

Contact us!

If you would like to learn more about our products and services, or would like to request a customized offer, please do not hesitate to contact us. You can contact us by phone, via email or by using our contact form. We look forward to receiving your enquiry!